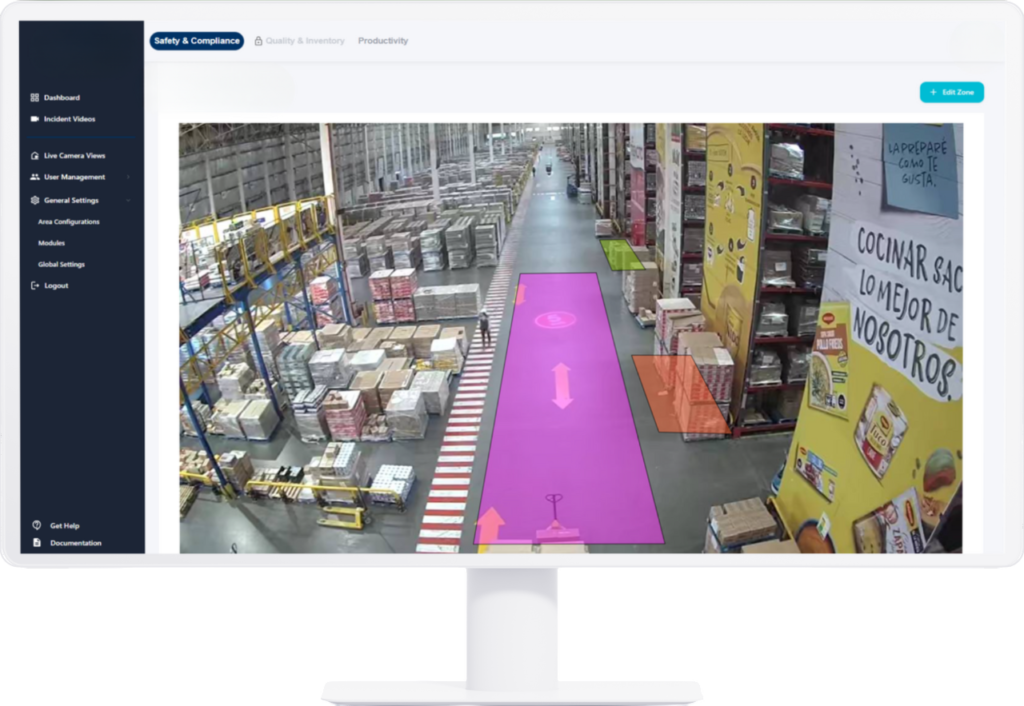

What happens when AI hits the warehouse floor? See it live in the Arvist Experience Center.

See AI in action on the warehouse floor

Book Your VisitYour warehouse operations should catch every error before it reaches your customer.

Arvist helps your team work smarter with automated insights across your inventory, so you can reduce errors and streamline operations.

Monitor every pallet, package, and cycle count in real time. Arvist catches errors as they happen so you can prevent costly mistakes.

Arvist plugs directly into your WMS and ERP, syncing inspection data for real-time visibility and faster decision making.

Arvist handles repetitive tasks so your team can focus on higher-value work and avoid burnout.

Real savings and efficiency gains in just 1–2 months.

Connects to existing infrastructure instantly, without slowing down your workflow.

Arvist delivers proven results where precision, efficiency, and uptime matter most.

QC in a Box is a plug-and-play inspection station that delivers instant computer vision for your warehouse. Ships pre-configured and ready in a day, it automates quality control across packing tables, pallet checks, and more—cutting errors, claims, and labor costs without disrupting

workflows.

You’ve got the questions, we’ve got the answers.

Arvist automates warehouse QC using your existing infrastructure, including cameras, scanners, and WMS data, detecting damaged goods, labeling errors, expired items, and short or over-shipments in real time.

Arvist connects directly with over 80 leading WMS and ERP platforms, syncing inspection data and visual inputs so you get real-time visibility without lengthy IT projects.

Not necessarily. Arvist works with existing security cameras, tablets, or warehouse hardware. If you need extra cameras, lightweight kits for quick installation are available.

Most customers go live within one day per QC station. Deployment is fast and does not disrupt your normal workflow.

No. Arvist runs alongside your workflows, adding automated inspections and intelligence without requiring major changes to your processes.

Many warehouses see savings and efficiency gains within one to two months, through reduced claims, fewer shipment errors, lower labor costs, and improved on-time, in-full performance.

Arvist is fully configurable without code. You choose what to track, who gets alerts, and how information flows. The system adapts to your warehouse workflows instead of forcing you to adapt to it.

© 2026 Arvist. All rights reserved | Designed by Moonshot Advisory