From damage detection to compliance assurance, Arvist delivers Al-powered visibility and control for every shipment.

Arvist automates quality control, compliance, and visual audits on your current infrastructure, without disrupting workflows. 90% of warehouse activity happens at the loading dock. Arvist brings precision where it matters most.

Automated quality control catches defects early, so you avoid expensive product damage and claims.

Automated inspections help ensure on-time, in-full deliveries with fewer errors and surprises.

Arvist handles repetitive tasks so your team can focus on higher-value work and avoid burnout.

Real savings and efficiency gains in just 1–2 months.

Deploy in hours, leverage existing systems, and keep workflows intact.

Arvist delivers proven results where precision, efficiency, and uptime matter most.

Automated inspections. Instant visibility.

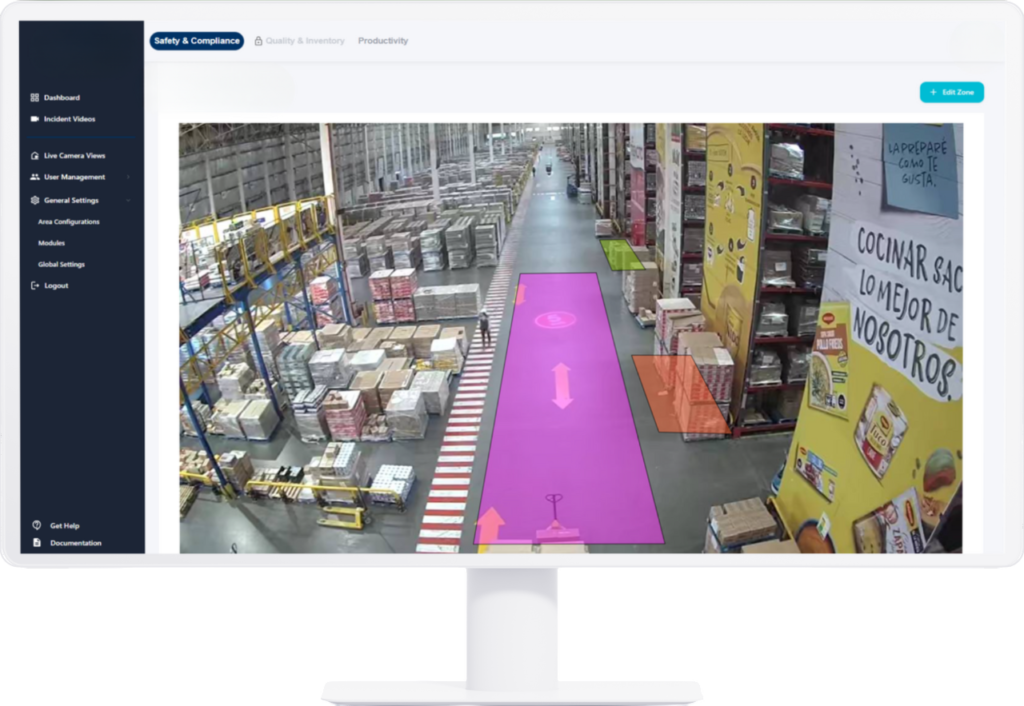

Proactive Safety and Compliance, in Real-Time

Traditional safety inspections miss risks and create gaps in compliance. Arvist detects hazards, enforces safety rules, and monitors restricted areas so your warehouse stays safe and compliant.

No matter your warehouse objectives, Arvist’s AI-powered inspections deliver real, trackable benefits today.

Already have a stack you love? Perfect. We plug right in and get to work alongside your existing systems and workflows.

When accuracy matters, warehouses choose Arvist for intelligent, automated insights.

Automate Quality Checks to meet Highest Standards

At USI, our commitment to excellence drove us to partner with Arvist. Their vision technology has not just met but exceeded our expectations, revolutionizing how we approach safety, compliance, and inventory control. With real-time safety tracking, AI-powered inspections, and automated quality checks, we're not just processing goods; we're ensuring they meet the high standards our clients deserve. This partnership has elevated our operations, enhancing both efficiency and client satisfaction.

Transform Safety & Ergonomics Monitoring

Arvist has done a fantastic job helping Holmatro see opportunities to utilize AI software. They originally came in to help with safety and ergonomics and ended up helping improve our building security and receiving process. They were very patient with us and listen to our needs. The software engineers not only took our information and created something great but they also added features we didn’t think possible. They have really gone above and beyond what we originally thought possible.

You’ve got the questions, we’ve got the answers.

Arvist automates warehouse quality control and compliance using the infrastructure you already have—like cameras, scanners, and WMS data. Our AI detects issues such as damaged goods, labeling errors, expired shipments, and short or over shipments in real time, helping reduce claims and improve delivery accuracy.

Arvist integrates with over 80 leading WMS and ERP platforms out of the box. We connect directly to your data streams, compare them against visual inputs, and provide real-time alerts and dashboards. No lengthy IT projects are needed.

Not at all. Arvist is designed to work seamlessly with the equipment you already have. You can use your existing security cameras, Zebra tablets, or other warehouse hardware with the Arvist platform. If additional cameras are required, we provide lightweight kits that can be installed in just a few hours.

Most customers are live within one day per QC station. Unlike traditional automation projects that take months, Arvist is built for quick setup so you see results immediately.

Arvist uses your existing security cameras in their current positions to monitor operations for compliance and safety risks. Our on-premise edge server connects directly with these cameras, ensuring data is processed securely without leaving your network.

Yes. Arvist meets SOC 2 and ISO 27001 standards for IT security. Our on-premise edge server eliminates the need for open ports or external data flows. For additional flexibility, clients can also integrate their own cloud storage for long-term archiving.

No. Arvist runs alongside your existing workflows. It doesn’t require major process changes or retraining. Think of it as an extra set of eyes and intelligence layered on top of your team’s work—fast, accurate, and always on.

Customers typically see Arvist pay for itself within 1–2 months by cutting claims, reducing rework, and improving OTIF performance. Beyond cost savings, it also builds trust with clients by providing photo and video proof for every claim.

Every warehouse runs differently, so Arvist is fully configurable without code. You decide what to track, who gets alerts, and how information is shared. The system adapts to your workflows instead of forcing you to adapt to it.

Keep up with the latest AI trends transforming warehouse performance.

© 2025 Arvist. All rights reserved | Designed by Moonshot Advisory